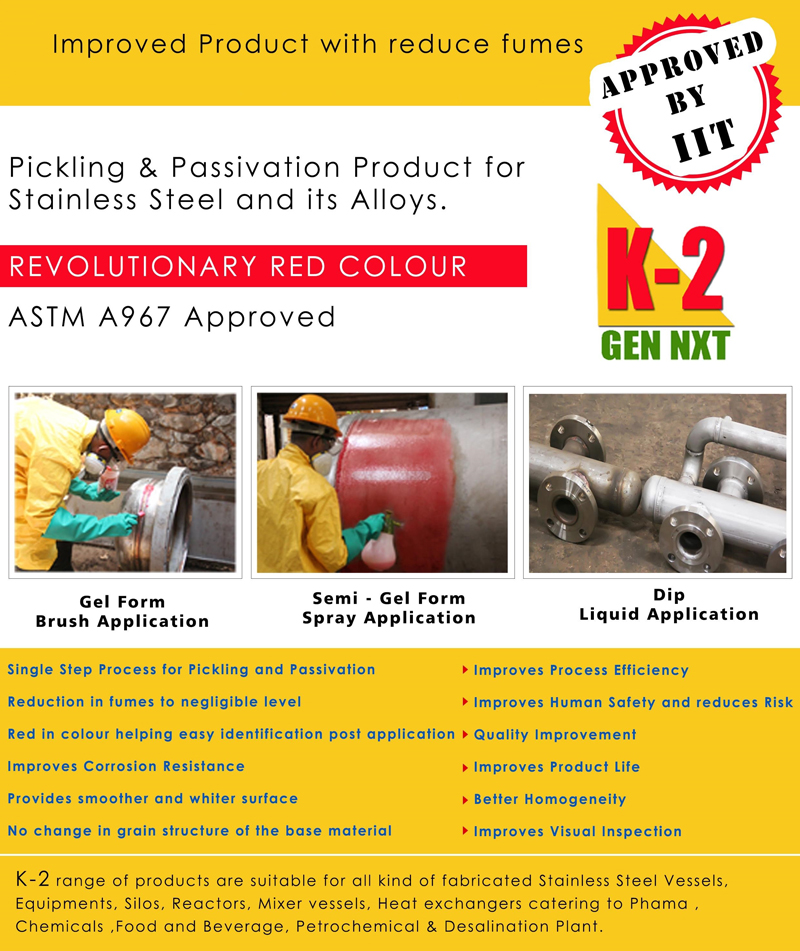

The chemical K-2 is available in 3 forms as follows giving the same results. Application of K-2 Passivation solution is a must after the application of all forms of K-2 chemical in order to avoid further corrosion and contamination.

It is used to clean weld seams and the areas surrounding the welds.

ACHIEVEMENT ATTAINED BY USING K-2

1. Get rid of welding scales without wire brushing or grinding.

2. Removes all types of scales, rust particles annealing colours, metallic and organic contaminates from large areas of fabricated stainless steel.

3.Removes burn spots, discolourations, spot-welding colours, oxide scale formation caused by welding.

4. Gives a passive, clean, flawless, sterile, particle-free stainless steel.

5. Micro deburring takes place giving a uniform smooth and an even finish.

6. Descalement & deferroxyl treatment on stainless steel is achieved forming a perfectly pickled and passive coating.

7.There is no chance in the physical or chemical properties of the metal.